Imikhiqizo

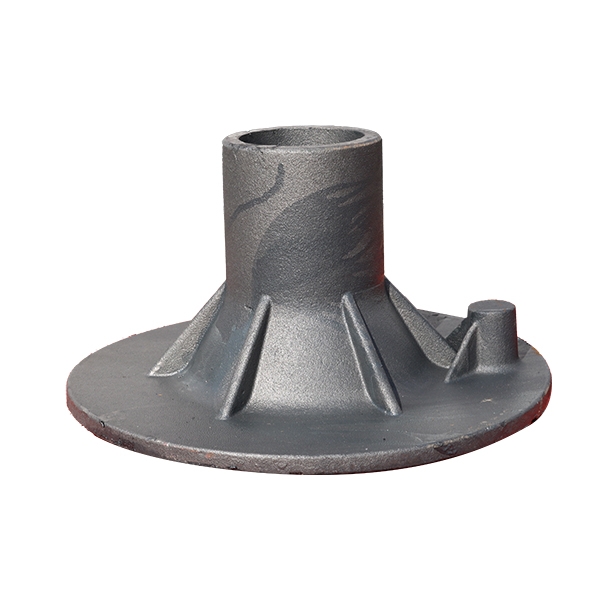

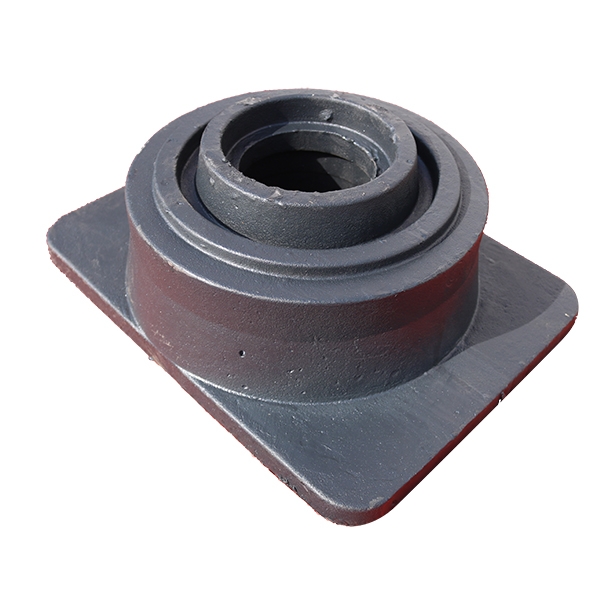

I-GVT150101555 HUB DISHRER

Isici Somkhiqizo

Ukulahleka kwe-foam elahlekile (eyaziwa nangokuthi i-real mold casting) yenziwe nge-foam plastic (i-EPS, i-stmma noma i-epmma) i-polymer izinto ezibunjiweyo nosayizi ofanayo njengoba izingxenye ezizokhiqizwa futhi zihlanganiswe, futhi zihlanganisiwe Nge-Refractory Coating (eqinisiwe), ebushelelezi futhi ephefumula) futhi yomisiwe, ingcwatshwa esihlabathini esomile se-quartz futhi yabekwa ngaphansi kokuvota okuphefumulayo okunezinhlaka ezintathu. I-molten Metal ithululelwa ebhokisini lesihlabathi lokubumba ngaphansi kwengcindezi engemihle, ukuze imodeli yezinto ezibonakalayo ifudunyezwa futhi ihlungwa, bese ikhishwe. Indlela entsha yokuphonsa esebenzisa insimbi ewuketshezi ukuze isule inqubo yesikhathi sokuphonsa isikhathi esisodwa esakhiwe ngemuva kokupholisa nokuqina ukuze ikhiqize izinqubo. Ukuphosa okulahlekile kwe-foam kunezici ezilandelayo: 1. Izinkontileka zingekhwalithi enhle nezindleko eziphansi; 2. Izinto zokwakha azilinganiselwe futhi zilungele bonke osayizi; 3. Ukunemba okuphezulu, indawo ebushelelezi, ukuhlanzwa okuncane, kanye nemishini emincane; I-4. Izinkinga zangaphakathi zincishiswa kakhulu futhi ukwakheka kokuphonsa kwenziwa ngcono. Mnene; I-5. Ingabona ukukhiqizwa okukhulu nokukhiqizwa kwesisindo; 6. Ilungele ukukhiqizwa kokukhiqizwa kwabantu abaningi kakhulu; 7. Ilungele ukusebenza kwezandla kanye nokukhiqizwa komugqa okuzenzakalelayo komhlangano nokulawulwa kokusebenza; 8. Isimo sokukhiqizwa somugqa wokukhiqiza sihlangabezana nezidingo zamapharamitha okuvikela ezemvelo. ; 9. Ingayithuthukisa kakhulu imvelo yokusebenza kanye nemibandela yokukhiqiza yomugqa wokukhiqiza, ukunciphisa amandla abasebenzi, futhi unciphise ukusetshenziswa kwamandla.

Ukuchazwa Komkhiqizo

1. Vacuum ephansi ingcindezi elahlekile ye-foam casting technology. Kuhlanganisa nezinzuzo zobuchwepheshe zokuphonsa kwengcindezi ephansi kanye ne-vacuum elahlekile foam cast, kuqeda inqubo yokugcwalisa ngaphansi kwengcindezi yomoya etholakalayo, futhi kuthuthukisa kakhulu amandla okugcwalisa we-alloy. Uma kuqhathaniswa nokudla okufa, ukutshalwa kwezimali kuncane, izindleko ziphansi, futhi ama-cassings angaqiniswa ukwelashwa okushisa; Uma kuqhathaniswa nokuphonswa kwesihlabathi, ama-castings anokunemba okuphezulu, ubulukhuni obuphansi obuphansi, ukukhiqiza okuphezulu, nokusebenza okuhle. Ngaphansi kwesenzo sokulwa namandla adonsela phansi, i-Sprue iba yisiteshi sokufushanisa, kanye nokulahleka kokushisa okuthulula kuncane. Uhlelo lokuthulula lwe-Alloy Castings lulula futhi luyasebenza, ngesivuno esiphezulu nesakhiwo esikhulu. Izinga lokushisa elisheshayo elidingekayo liphansi futhi lilungele ukuthulula nokwakhiwa kwama-alloys ahlukahlukene angewona ama-ferrous. .

I-2.prestrere elahlekile ye-foam casting technology. Kuhlanganisa ubuchwepheshe obulahlekile be-foam Umgomo wawo uzothulula insimbi ebiwe ethangini elinengcindezi elinebhokisi lesihlabathi ukwenza isikhunta segwebu lishonile futhi linyamalale, bese simisa uphawu lwethangi lokucindezela bese lwethula igesi engcindezini ethile. , okwenza i-molten Metal iqinise futhi icwebe ngaphansi kwengcindezi. Isimo salobu buchwepheshe ukuthi singanciphisa kakhulu amaphutha okuphonsa anjenge-shrinkage, i-shrinkage poor, kanye nama-pores ekukhokhisweni, futhi athuthukise ubungako bama-castings. Ukuqina ngaphansi kwengcindezi yangaphandle kungadala ukuguqulwa kwemicroscopic kwama-dendrites aqaliswe ekuqaleni, kuthuthukisa kakhulu umthamo wokuphakelayo we-riser futhi uthuthukise ukushwabana kwangaphakathi kokupholisa. Ngasikhathi sinye, ingcindezi inyusa i-solubity yegesi ku-alloy eqinile, okwenza sikwazi ukucacisa. Ama-bubble ancishisiwe.

Ufuna ukuxoxa ngalokho esingakwenzela khona?

Hlola ukuthi izixazululo zethu zingakuthatha kuphi.