Imikhiqizo

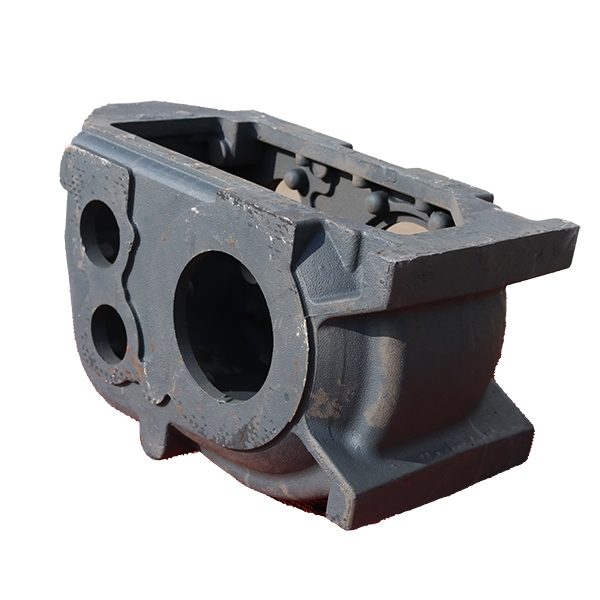

604.39.295 Ukuxhuma ishubhu

Isici Somkhiqizo

Ukulahleka kwe-foam elahlekile (eyaziwa nangokuthi i-real mold casting) yenziwe nge-foam plastic (i-EPS, i-stmma noma i-epmma) i-polymer izinto ezibunjiweyo nosayizi ofanayo njengoba izingxenye ezizokhiqizwa futhi zihlanganiswe, futhi zihlanganisiwe Nge-Refractory Coating (eqinisiwe), ebushelelezi futhi ephefumula) futhi yomisiwe, ingcwatshwa esihlabathini esomile se-quartz futhi yabekwa ngaphansi kokuvota okuphefumulayo okunezinhlaka ezintathu. I-molten Metal ithululelwa ebhokisini lesihlabathi lokubumba ngaphansi kwengcindezi engemihle, ukuze imodeli yezinto ezibonakalayo ifudunyezwa futhi ihlungwa, bese ikhishwe. Indlela entsha yokuphonsa esebenzisa insimbi ewuketshezi ukuze isule inqubo yesikhathi sokuphonsa isikhathi esisodwa esakhiwe ngemuva kokupholisa nokuqina ukuze ikhiqize izinqubo. Ukuphosa okulahlekile kwe-foam kunezici ezilandelayo: 1. Izinkontileka zingekhwalithi enhle nezindleko eziphansi; 2. Izinto zokwakha azilinganiselwe futhi zilungele bonke osayizi; 3. Ukunemba okuphezulu, indawo ebushelelezi, ukuhlanzwa okuncane, kanye nemishini emincane; I-4. Izinkinga zangaphakathi zincishiswa kakhulu futhi ukwakheka kokuphonsa kwenziwa ngcono. Mnene; I-5. Ingabona ukukhiqizwa okukhulu nokukhiqizwa kwesisindo; 6. Ilungele ukukhiqizwa kokukhiqizwa kwabantu abaningi kakhulu; 7. Ilungele ukusebenza kwezandla kanye nokukhiqizwa komugqa okuzenzakalelayo komhlangano nokulawulwa kokusebenza; 8. Isimo sokukhiqizwa somugqa wokukhiqiza sihlangabezana nezidingo zamapharamitha okuvikela ezemvelo. ; 9. Ingayithuthukisa kakhulu imvelo yokusebenza kanye nemibandela yokukhiqiza yomugqa wokukhiqiza, ukunciphisa amandla abasebenzi, futhi unciphise ukusetshenziswa kwamandla.

Ukuchazwa Komkhiqizo

Idizayini iyavumelana nezimo futhi ihlinzeka ngenkululeko eyanele yokuphonsa ukwakheka kwesakhiwo. Ukukhokhiswa okuyinkimbinkimbi kakhulu kungaphonswa ngokuhlanganiswa kwezikhunta zegwebu.

Yehlisa izindleko zokutshala imali kanye nezindleko zokukhiqiza, ukunciphisa isisindo sokuphonsa izikhala, futhi ube nezimali ezincane zemishini. .

Akunasisekelo sakwaSand ngokuxoshwa kwendabuko, ngakho-ke ngeke kube khona ubukhulu obungalingani bodonga lokukhokhiswa okubangelwa usayizi ongelona iqiniso noma isikhundla esingesilo esiyisisekelo sokuphonswa kwesihlabathi sendabuko.

.Castcaings ukunemba okuphezulu. Ukuphonsa kwe-Foam elahlekile kuyinqubo entsha engenambhalo futhi awukho ubumba olunembile. Le nqubo ayidingi isikhunta ukuthatha, akukho ndawo yokuhlukanisa, futhi akukho mgogodla wesihlabathi, ngakho-ke ama-castings awanawo ama-flash, ama-burrs, namaphutha asalungiswa okubangelwa yinhlanganisela eyinhloko ancishisiwe. Ubulukhuni be-castings bungafinyelela ra3.2 kuya ku-12.5μm; Ukunemba okuyisisekelo kokusakazwa kungafinyelela ku-CT7 kuye ku-9; Isibonelelo semishini singu-1.5 kuye ku-2mm okungenani, esinganciphisa kakhulu izindleko zemishini. Uma kuqhathaniswa nendlela yokusakaza yesihlabathi yendabuko, kungancishiswa ngo-40% kuya ku-50% wesikhathi semishini.

Ukukhiqizwa okuhlanzekile, azikho ama-Chemical Binders esihlabathini sokubumba, amapulasitiki e-Foam anobungani bemvelo emazingeni okushisa aphansi, kanti izinga lokuphinda lisebenze kabusha lesihlabathi esidala lingaphezulu kwama-95%.

Ufuna ukuxoxa ngalokho esingakwenzela khona?

Hlola ukuthi izixazululo zethu zingakuthatha kuphi.